Home » Precihole

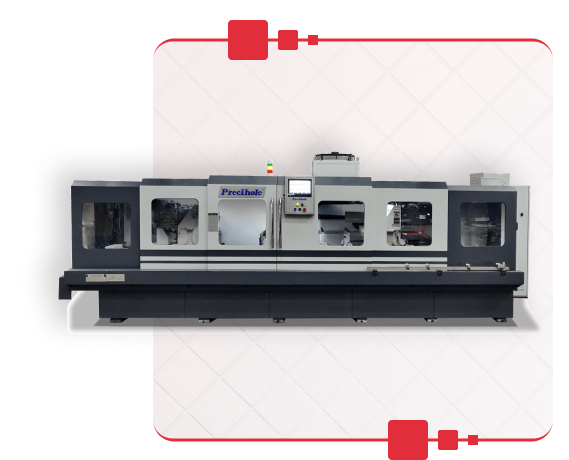

We offer advanced deep hole drilling solutions designed for high accuracy, consistent performance, and operational reliability. Our machines and application support are built to handle demanding requirements across a wide range of industries, including automotive, aerospace, oil & gas, and medical manufacturing.

From micro-diameter drilling starting at Ø1 mm to large-scale holes up to Ø400 mm, and drilling lengths reaching 12 meters, our solutions are engineered to deliver exceptional results even in the most challenging applications.

Precihole manufactures a special purpose, highly versatile machine for facing and chamfering of barrel blanks. Accuracy on these operations is critical for the barrel blank to be located and aligned properly in the cone clamping system on gun drilling and pull reaming machines. If the barrel is improperly faced or chamfered, the barrel does not seat properly in the cone leading to inaccuracies in the gun drilling operation. This machine engages the component simultaneously at both ends.

Precihole’s Vertical honing machines are next gen solutions that provide state of the art features and world class performance while providing the best value in the industry. They are designed to hone holes from Ø5 mm(0.2″) to Ø50 mm (2″) and part lengths of upto 1500 mm (60″) long. They are complete solutions comprising of machine, tooling, tooling accessories and honing oil suited perfectly for gun barrel honing.

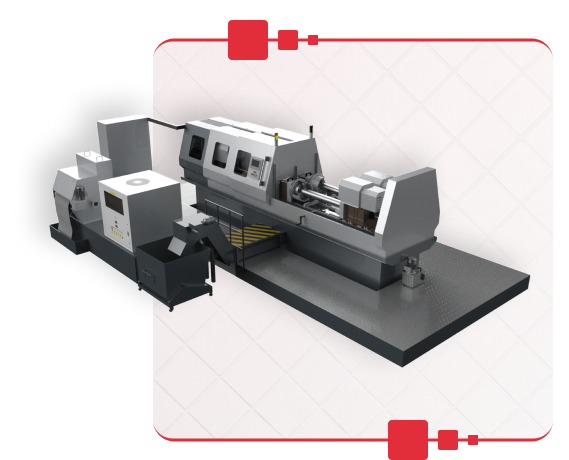

Precihole’s XYGVNCL Series Column Type Multi Axis Gun Drilling Machines satisfy all requirements for drilling and milling of multiple deep holes in large size molds for Die and Mold industry and Tube sheets. Machines can be customized to accommodate size and stroke requirements. These machines provide excellent location accuracy and repeatability, straightness, surface finish and bore tolerance.

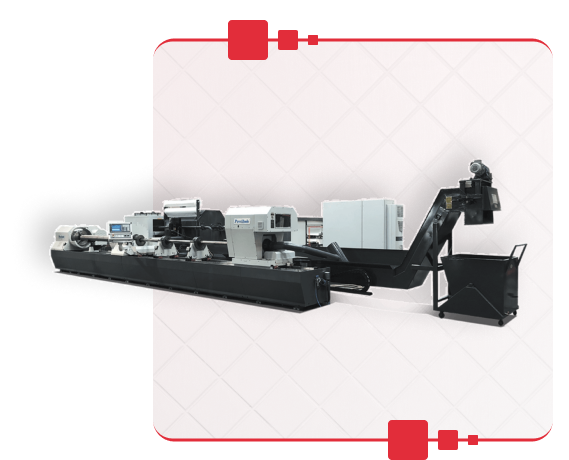

Precihole’s SBN Series Skiving and Roller Burnishing Machines are built to operate in a high production mode for accurate size & best bore finished hydraulic cylinder tubes. Machines incorporate use of state of the art technology that enables cycle times to be 30-40 times faster than honing. Machines are customized to suit volume requirements and provide excellent surface finish and wall thickness consistency across the length of the tube.

Precihole’s Gun Drill Regrinding Machines are built for precise resharpening of gun drills in a single setup. These machines are versatile and improve turnover for sharpening gun drills. They are operator friendly and incorporate a range of drills from Ø2.5 mm to Ø 30 mm.

We start with a detailed understanding of what you need: diameter, depth, material, surface finish, tolerances.

Based on your specs, we recommend one of our machine series (Gun, BTA, Honing, etc.) or a custom‐engineered solution.

We manufacture, test, and deliver—with precision tooling and documentation. Our facilities are ISO certified; we guarantee straightness and finish.

After your machine is in place, we provide training, tooling, spare parts, and optional subcontract services. We also offer finishing processes (honing, etc.) if you don’t own finishing equipment.

FEELER machines are built to stringent specs for minimal vibration, high repeatability.

Feeler gauges are calibrated, durable, rust-resistant materials.

Gauge tool prices begin at competitive rates; machine quotes include shipping & support.

Installation, operator training, spare parts & maintenance.

Based in Ahmedabad, Gujarat. Quick response, local service network.

Deep hole drilling refers to drilling operations where the depth of the hole is large relative to its diameter—often several times greater (e.g. l/D ratio > 3, sometimes

much more). Precihole handles diameters from Ø1 mm up to Ø400 mm and depths up to 12 meters. precihole.com

We maintain high standards for straightness, bore tolerance, and surface finish. Depending on process (gun drilling + honing etc.), finishes can be very tight (as required by aerospace or medical components).

Yes. We operate subcontract deep hole drilling & finishing services for clients who don’t want to invest in equipment. precihole.com

Lead times depend on specifications (diameter, customisations, tooling). We aim to offer competitive delivery schedules—contact us with your specs for a precise timeline.

Ownership involves upfront cost, tooling, maintenance; outsourcing gives flexibility without capital investment. We can help you make a cost-benefit analysis.

+91 98256 25740

+91 75748 53140

info@sre-group.in

support@sre-group.in

jaydeep@sre-group.in

A/FF/2,3,4 Pushpak Estate, Gujarat Bottling Road, Rakhial, Ahmedabad, Gujarat,380023